Exhibition Preview | Gantte invites you to attend the China Peptide Industry Conference in May

The 4th China Peptide Industry Conference will be held at Doubletree by Hilton Hangzhou Heda on May 10-11, 2025. The conference exchanged and discussed topics such as the interpretation of policies and regulations on peptide drugs, cutting-edge discoveries of innovative drugs, new synthesis technologies, new production processes, quality research, drug application, and innovative applications of new bioactive peptides, aiming to promote the innovative development of the entire peptide industry chain in China.

In recent years, the efficient preparation of polypeptide powder has become one of the focuses of academic and industrial attention in the fields of biomedicine and functional food. To address the problems of long drying time, low drying efficiency, high energy consumption and fragile peptide activity in traditional peptide drying methods, Shanghai Gante brings a new green and low energy consumption option for peptide drying production ---- "MSD spray drying technology"!

PART 01 Product Introduction

MSD spray drying technology is a mild and low-temperature drying technology that uses a mild and controllable drying medium to efficiently and rapidly dry the liquid medicine with low energy consumption. For heat-sensitive products such as polypeptides, it consumes 40%-70% less energy than traditional drying equipment without damaging the peptide chain! Bring more efficient and greener drying and granulation solutions to the industry.

Low-temperature drying: Rapid drying of the material liquid at low temperatures without damaging the activity of the polypeptide product. The particle size of the powder is uniform and controllable. The product can be harvested in particle sizes ranging from 2 to 300 microns, and the moisture content can be reduced from 1% to 10%.

High production efficiency: Continuous production, breaking through the limitations of batch production, capable of continuous drying and material collection, with a yield as high as 95% to 99%.

Energy conservation and consumption reduction: Low energy consumption production. Compared with traditional drying of heat-sensitive materials, energy consumption can be reduced by 40% to 70%.

Intelligent and green: For toxic and harmful solvents, it can achieve a closed process and efficiently recover solvents. Configurable CIP/SIP, highly efficient cleaning without blind spots, meeting GMP production requirements, and ensuring clean production.

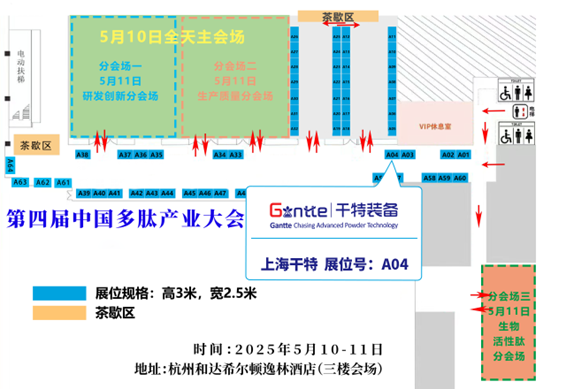

PART 02 Special Exhibition Booth

Exhibition Time: May 10-11, 2025

Exhibition Venue: Doubletree by Hilton Hangzhou Heda

Exhibition Number: A04

Welcome everyone to visit our booth for guidance and exchange