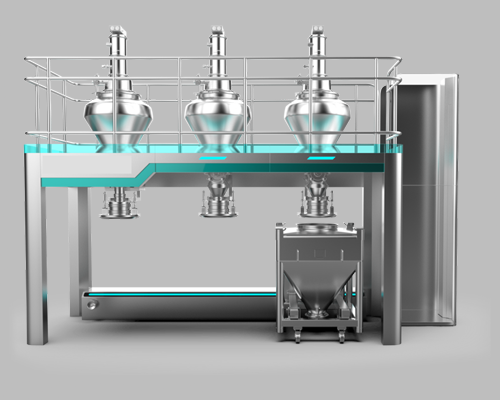

1. The entire process is under aseptic control, eliminating the risk of process contamination and meeting the requirements of aseptic production.

2. Configurable CIP/SIP, efficient cleaning without dead corners, meeting GMP production requirements, and ensuring clean production.

3. The drying temperature is gentle and controllable, without damaging the activity of the product.

4. Efficient drying ensures that the moisture content is as low as 1%-10%.

5. The powder's particle size is uniform and controllable, and the granulation's microstructure is also controllable.

6. High production efficiency and continuous production. Continuous drying and material collection break through the limitations of batch production, with a yield as high as 95% to 99%.

7. Low energy consumption production. Compared with the traditional drying of heat-sensitive materials, energy consumption can be reduced by 40%-70%, significantly lowering the drying cost.

8. Green production. For toxic and harmful solvents, the process can be sealed and solvents can be recovered efficiently.

9. Product formula function, one-click automatic/semi-automatic production.

10. Intelligent software is used to manage production and achieve the best benefits.