1. Intelligent logistics - Material management with full-process tracking and traceability. The production process is transparent and visualized, and can be associated with the MES system to achieve batch production process tracking and quality traceability, ensuring data integrity and reliability.

2. Intelligent systems - Intelligent devices, control systems, and information management systems are interconnected and effectively integrated, collecting and controlling data in real time to enhance production efficiency and continuity.

3. Intelligent control - Ensuring production quality and batch consistency. Based on industrial big data technology, production data analysis is carried out to achieve precise intelligent process control

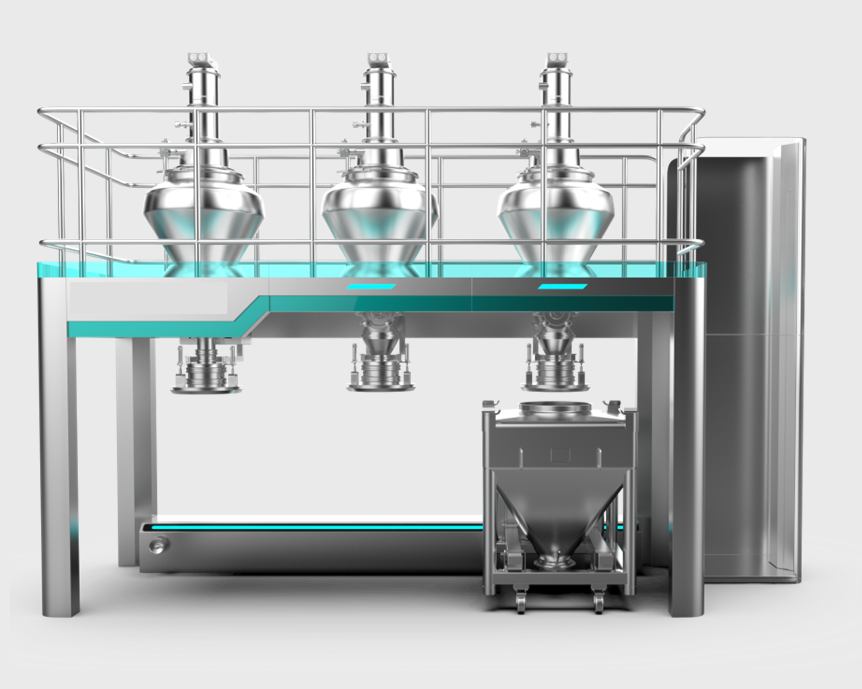

4. Customized production of craftsmanship, quality stems from design. Design the powder system based on the product process, including combined feeding, aseptic feeding, closed feeding, multi-component mixing, long-distance conveying, and continuous production... Meet the GMP production design requirements, optimize the process and improve production efficiency.

5. There is no leakage in the production process, ensuring safe production. Based on the material characteristics and production requirements, process design is carried out to ensure that the process is free of leakage and hazards.

6. Optional CIP/WIP is available for batch change without cross-contamination, ensuring safety and no pollution.